THE COST OF DATA CENTER WHITESPACE IS ON THE RISE, POWERED IN NO SMALL PART BY THE AI BOOM.

Rental rates

In North America, rates in Q1 2025 rose, though at a slower rate compared with the previous year. Chicago and Northern Virgina saw the biggest increases of 14.7% and 15%, respectively. In Europe, rental rates rose across four key markets, including in London where average rent went from $160-195 per kW per month to $180-$215 year-on-year.1

Vacancy rates

Globally, weighted average data center vacancy rates dropped 2.1% year-on-year in the first half of 2025. In North America, vacancy rates remained low in Q1 2025, with Northern Virginia remaining the tightest market at 0.76%—up slightly from 0.1%. Atlanta saw the largest vacancy rate drop from 8.8% to 3.6%.

In Europe’s top four markets, overall vacancy rates fell by 3.2% year-on-year in Q1 2025 to a record low of 7.4%.2

THE BIGGER PICTURE

Between 2025 and 2030, McKinsey & Company estimates AI workloads alone will increase from 44GW to 156GW.3 A sign that demand for data center real estate will remain high.

Are your batteries eating into valuable whitespace?

With real estate increasingly at a premium, saving whitespace is a no-brainer for data centers. However, it’s usually easier said than done.

Batteries form a key part of data centers’ UPS—kicking in whenever needed to prevent that notoriously costly downtime. Each data center has specific requirements about how much energy they need from their batteries.

How much energy can be stored within a particular space depends on the batteries’ energy density. Batteries with low energy density mean you’ll need more batteries to meet your energy needs. More batteries mean more space occupied.

HOW DO YOU KNOW THAT YOUR CURRENT SETUP IS MAXIMIZING DATA CENTER WHITESPACE? ARE OUTDATED BATTERIES WITH LOW ENERGY DENSITY TAKING UP ROOM IN YOUR DATA CENTER AT THE EXPENSE OF REVENUE-GENERATING SERVERS?

PLATE THICKNESS AND ENERGY DENSITY IN BATTERIES: WHAT DO THESE MEAN FOR DATA CENTERS?

In the world of battery design, plate thickness plays a critical role in determining how much energy a battery can store—and how much space it takes up. For data centers, where whitespace is at a premium, this design detail can have significant implications.

What is a battery plate?

A battery plate is composed of two main components: grid and paste (active material.) The grid acts as a conductor and structural support, while the paste is where the electrochemical reactions occur. The design and composition of these plates directly influence the battery’s performance, energy density, and lifespan.

Thinner plates = higher energy density

Research shows that thinner plates tend to be more reactive, allowing for better utilization of active material and higher energy density. A study published in the Journal of Solid State Electrochemistry used 3D modeling to demonstrate that thicker plates can lead to uneven current distribution, increased internal resistance, and reduced energy efficiency—especially at high discharge rates.4

The alloy dilemma: energy vs. longevity

When batteries use non-lead alloys in their grids, manufacturers can face a trade-off. Thinner plates made from these materials can boost energy density, but they’re more vulnerable to grid corrosion, which shortens battery lifespan. Conversely, thicker plates with more sacrificial material can resist corrosion longer, extending lifespan—but at the cost of energy density and increased physical footprint.

SOME BATTERIES MARKETED AS ‘PURE LEAD’ MIGHT NOT BE EXACTLY AS THEY SEEM. WHILE THE ACTIVE MATERIAL MAY BE PURE LEAD, THE BATTERIES OFTEN USE A NON-LEAD ALLOY, EXACERBATING THE ENERGY VS. LONGEVITY DILEMMA.

IMPLICATIONS FOR DATA CENTERS

This leads to a critical question for data centers using ‘pure lead’ batteries: Should you prioritize space savings or battery longevity?

- Thinner plates mean higher energy density, allowing batteries to occupy less whitespace but possibly with the drawback of more frequent and costly replacements.

- Thicker plates may offer longer service life, reducing replacement frequency but consuming more valuable floor space.

FREEING UP WHITESPACE WITHOUT COMPROMISE

What if data centers no longer had to choose between energy density and battery lifespan? What if you could maximize valuable whitespace without facing more frequent costly battery replacements?

Unlike conventional lead-acid batteries, TPPL batteries use pure lead grids and pure lead active material. This allows for thinner plates, offering higher energy density. At the same time, the use of pure lead slows down grid corrosion, significantly improving battery lifespan compared to batteries that use non-lead alloys.

Find out more about the enersys tppl advantage

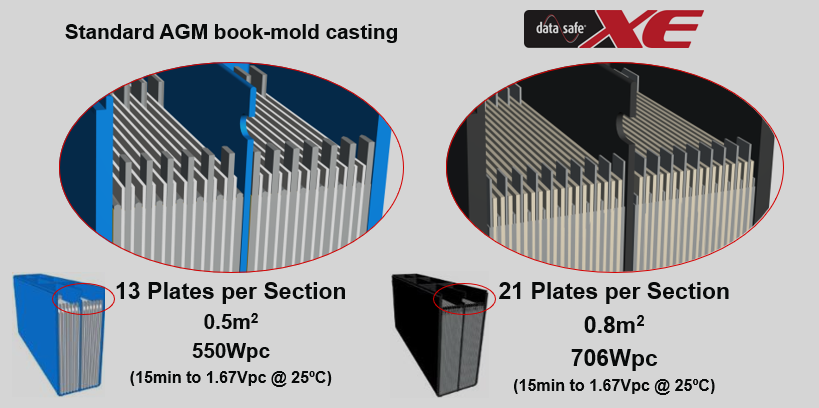

TO PUT THIS INTO PERSPECTIVE…

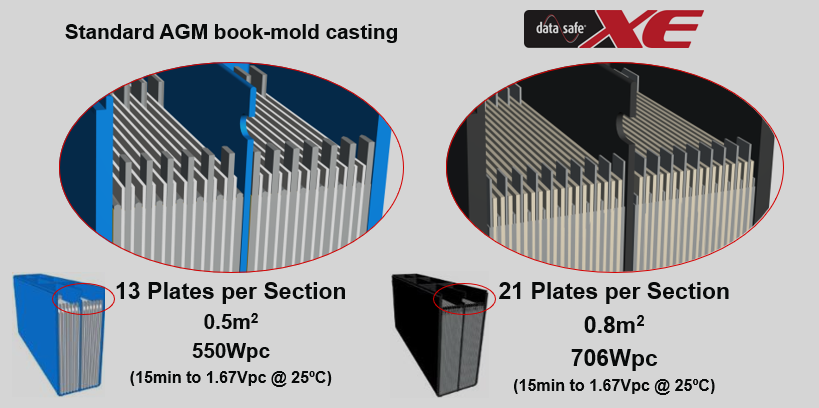

A standard AGM battery typically contains 13 plates per section, delivering around 550 watts per cell (Wpc). In contrast, the DataSafe® XE battery—a TPPL solution—features 21 plates per section, delivering a much higher 706 Wpc. In short, TPPL batteries pack more energy into the same space.

|

HOW TPPL DELIVERED EXTRA WHITESPACE FOR A MAJOR COLOCATION DATA CENTER

After switching to DataSafe® XE batteries, a data center in northern Italy reduced the amount of physical space occupied by their batteries by 25%. More whitespace, more revenue-generating servers, and better for their bottom line.

Click HERE to read the full case study.