WHY ENERSYS?

WHY ENERSYS?WHO WE ARE

WHO WE ARECOMPANY BACKGROUND

COMPANY BACKGROUNDLEADERSHIP

LEADERSHIPINVESTORS

INVESTORSCAREERS

CAREERSSUSTAINABILITY

SUSTAINABILITYNEWS

NEWSMANUFACTURING LOCATIONS

MANUFACTURING LOCATIONSSUPPLIERS

SUPPLIERSQUALITY

QUALITYINDUSTRIES

COMMUNICATIONS NETWORKS

View all COMMUNICATIONS NETWORKSTHE POWER OF 5G

View all THE POWER OF 5GLOGISTICS & WAREHOUSING

View all LOGISTICS & WAREHOUSINGTRANSPORTATION

View all TRANSPORTATIONCABLE BROADBAND

View all CABLE BROADBANDDATA CENTER

View all DATA CENTERINDUSTRIAL POWER & UTILITIES

View all INDUSTRIAL POWER & UTILITIESAEROSPACE & DEFENSE

View all AEROSPACE & DEFENSESAFETY & SECURITY

View all SAFETY & SECURITYMEDICAL

View all MEDICALBATTERIES

VIEW MORE BATTERIESCHARGERS

VIEW MORE CHARGERSMONITORING & FLEET MANAGEMENT

VIEW MORE MONITORING & FLEET MANAGEMENTENERGY SYSTEMS

VIEW MORE ENERGY SYSTEMSCABLE BROADBAND SOLUTIONS

VIEW MORE CABLE BROADBAND SOLUTIONSSERVICES

VIEW MORE SERVICESDC POWER SOLUTIONS

VIEW MORE DC POWER SOLUTIONSDC POWER DISTRIBUTION

VIEW MORE DC POWER DISTRIBUTIONAC POWER SOLUTIONS

VIEW MORE AC POWER SOLUTIONSAC POWER DISTRIBUTION

VIEW MORE AC POWER DISTRIBUTIONCONTROLLERS & COMMUNICATIONS

VIEW MORE CONTROLLERS & COMMUNICATIONSREMOTE LINE POWER SOLUTIONS

VIEW MORE REMOTE LINE POWER SOLUTIONSENCLOSURES & RACKS

VIEW MORE ENCLOSURES & RACKSJOIN OUR TALENT NETWORK

JOIN OUR TALENT NETWORKENERSYS INTERNSHIP PROGRAM

ENERSYS INTERNSHIP PROGRAMWHO WE ARE

WHO WE AREWHY JOIN?

WHY JOIN?ABOUT US

ABOUT USSEARCH JOBS

SEARCH JOBSCAREERS FOR VETERANS

CAREERS FOR VETERANSSUSTAINABILITY REPORT

SUSTAINABILITY REPORTENVIRONMENTAL, HEALTH & SAFETY MANAGEMENT

ENVIRONMENTAL, HEALTH & SAFETY MANAGEMENTHUMAN RIGHTS

HUMAN RIGHTSETHICS & COMPLIANCE

ETHICS & COMPLIANCESUSTAINABLE PROCUREMENT

SUSTAINABLE PROCUREMENTINDUSTRY ASSOCIATIONS

INDUSTRY ASSOCIATIONSCOMMUNITY ENGAGEMENT

COMMUNITY ENGAGEMENTSTORIES WORTH SHARING

STORIES WORTH SHARINGPOLICIES & REPORTS

POLICIES & REPORTSPEOPLE POWERING SUSTAINABILITY

PEOPLE POWERING SUSTAINABILITYINDUSTRY INSIGHT

INDUSTRY INSIGHTTRADE SHOWS & EVENTS

TRADE SHOWS & EVENTSENERSYS PULSE - BLOG

ENERSYS PULSE - BLOGLOGISTICS DEPARTMENT

LOGISTICS DEPARTMENTENERSYS FINANCIAL SOLUTIONS

ENERSYS FINANCIAL SOLUTIONSDOCUMENTS

DOCUMENTSSAFETY DATA SHEETS (SDS/MSDS)

SAFETY DATA SHEETS (SDS/MSDS)TOOLS

TOOLS

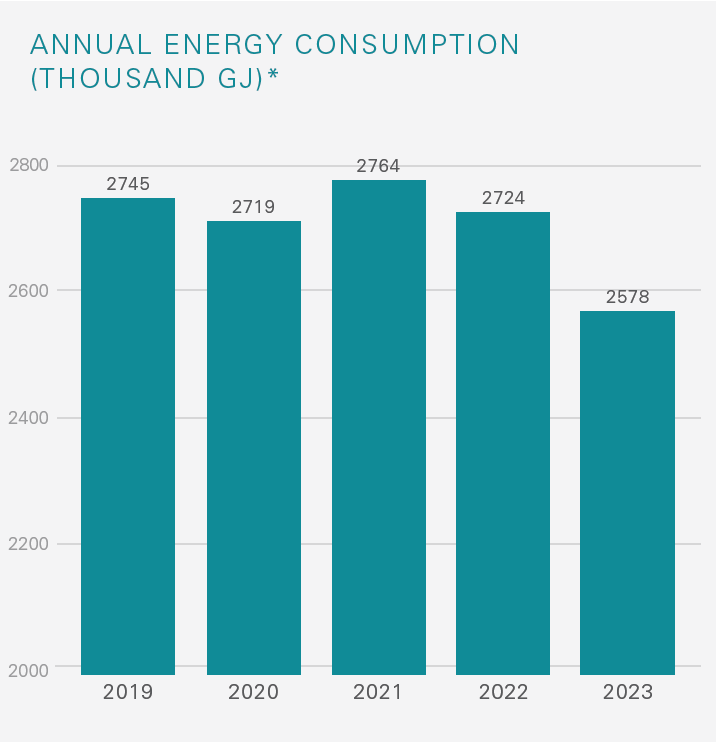

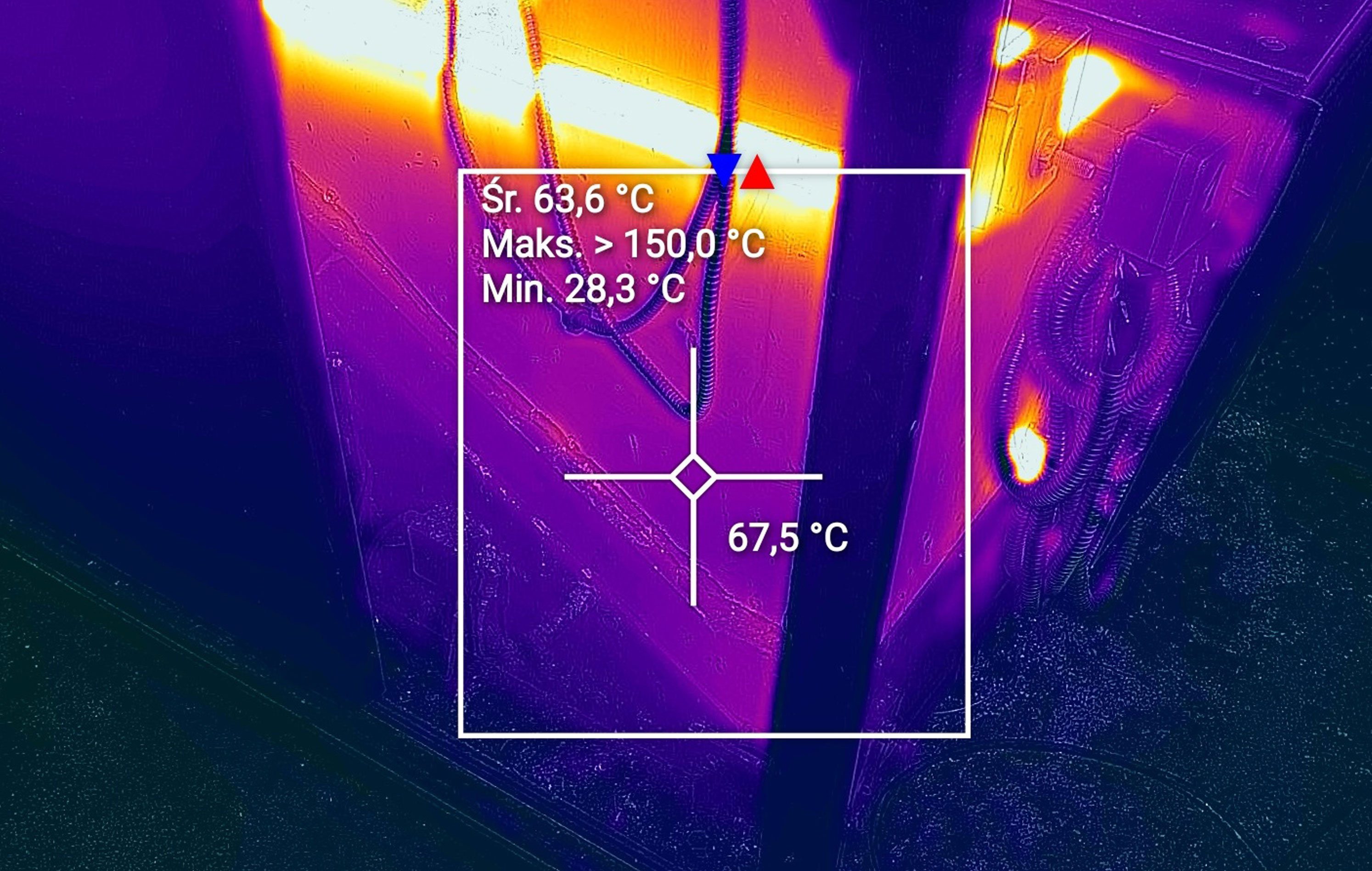

Thermal camera captures and measures heat loss reductions after insulation replacement.

Thermal camera captures and measures heat loss reductions after insulation replacement.